DMAIC and DMADV Are Methodologies of Six Sigma: A Complete Guide

1. What’s In This Guide? (Your Roadmap)

What’s the plan? This article is your map. We start with the basics of Six Sigma. That’s the base for everything. Then, I show you the two main toolkits.

I’ll share my insights. You will see how they are different, where they work best, and which one to pick for your next task.

2. Why Start With Six Sigma?

Before you get the tools, you need the mindset. Six Sigma is more than a trendy word. It’s a focus on near-perfect work. It kills the root cause of every mistake. The goal is to have less than 3.4 errors for every million tries. That’s a high bar that changes a business.

This is key. DMAIC and DMADV are methods for this main goal. They are the steps I use to get these great results. Without Six Sigma’s quality focus, the steps are just empty tasks. They are the “how-to” for meeting Six Sigma’s big goals.

This smart, data-first process ensures your business fixes are based on facts. Not just on guessing. I always say: follow the data, not what you think. This is how you build a great company.

3. What is the Core Purpose of DMAIC and DMADV?

Let’s start with the one you’ll use most: DMAIC. I say it “duh-may-ick.” It’s a five-step plan. I’ve used it many times to fix current processes that fail. The letters stand for Define, Measure, Analyze, Improve, and Control. Its goal is to dig deep. Find the real root of a bad problem. Then, set up a fix that lasts.

When I say they are Six Sigma methods, I mean they have specific jobs. dmaic and dmadv are methodologies of is your problem-solver. Are deliveries slow? Are there too many product errors? The dmaic and dmadv are methodologies of steps help you find the true issue. You make smart fixes. You stop the problem from coming back later.

Think of it as a planned way to react to a problem. You take a current, bad process. You tune it up. It then meets what the customer and the business need.

4. How Do the Five DMAIC Steps Work?

How does dmaic and dmadv are methodologies of lead to a fix? It’s a trip through five simple phases. You must not skip a step. I’ve seen projects fail when teams rush to a fix. This structure is vital. The system values being thorough over being fast.

Define: You and your team agree on the problem. What are you fixing? What does success look like?

Measure: Now, get the facts. This is a must. You must measure the current process to see where you start. This proves the fix worked later.

Analyze: This is the detective part. Use the facts to find the true root cause. Often, the real problem is not what you first thought.

Improve: When you know the root cause, you can set up a real fix. This is where you see the change.

Control: Last, you make it stick. You set up checks to watch the new process. This stops you from going back to old bad habits.

5. When Should You Use DMAIC?

When should you get out the dmaic and dmadv are methodologies of tool? The answer is easy: use it when you have a process that exists but is not working well. I once worked with a delivery firm. Their on-time rate had dropped fast. A perfect case for dmaic and dmadv are methodologies of . We did not need a new system. We just needed to find and fix the slow parts in the current one.

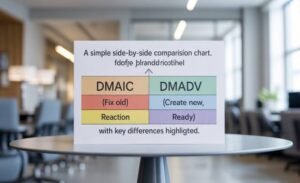

You must pick your tool well. DMAIC and dmaic and dmadv are methodologies of fix very different issues. If you have a process you can check, and you know it can be better, DMAIC is your way. It is built to fix and tune what you have now. Not to build from scratch.

Think of a phone center trying to cut wait times. Or a factory trying to cut errors. These are great times where DMAIC helps. It turns a bad process into a smooth, good one.

6. What Is DMADV?

Now, let’s talk about the other tool: dmaic and dmadv are methodologies of . I say it “duh-mad-vee.” DMAIC fixes what’s broken. DMADV builds it right from day one. I use this when a company makes a brand-new product or process. This is often called Design for Six Sigma (DFSS). The aim is to meet customer needs at a high quality level right away.

The letters mean Define, Measure, Analyze, Design, and Verify. Since both tools are Six Sigma, their goal is always quality. But dmaic and dmadv are methodologies of vis about stopping problems. It stops them before they even start. It builds quality into the design itself.

You use a DMADV project when there is no process to fix. Or when the current one is so bad that fixing it is a waste. It’s your plan for great new ideas.

7. How Does DMADV’s Process Differ?

The first few letters are the same. But the path with DMADV is quite new. The last two steps, in fact, show its new goal. This difference is key. The two tools have two separate jobs. One fixes things. The other creates things.

Define: The goals are set. Just like in DMAIC. Based on what the customer and business need.

Measure: You check what customers truly value. We call these Critical to Quality (CTQs).

Analyze: In this step, you check different design ideas. Which idea will best meet those customer needs?

Design: This is the creative part. You make a full plan for the new process or product. You go from a simple idea to a clear blueprint.

Verify: Last, you test the design. You run tests to check that it works. You ensure it truly pleases the customer.

8. When Should You Choose DMADV?

When do I tell a client to use DMADV? Choose it when you face an empty page. When you need a new product or service from the start. It is also the best choice when an old process is too broken to fix.

Knowing the right time is everything. The two tools are for specific uses. If a company wants to launch a new line of smart home gadgets, they must use dmaic and dmadv are methodologies of . It ensures the products are good and simple to use right away.

It’s about being ready, not fixing later. I’ve used it to plan new software, new factory lines, and new customer help steps. The goal is to get it right the first time.

9. Who Uses These Tools?

Who are the people, like me, leading these tasks? In the Six Sigma world, we use a belt system. I’m a Master Black Belt. That means I teach others. Project leaders are often certified Green Belts and Black Belts. They run the teams and the data daily.

These experts work in all fields. Factories, hospitals, tech firms, you name it. Since these tools are a pro skill, more firms train their staff. This builds an in-house team of problem-solvers.

But honestly, everyone on a team helps. The best projects I’ve worked on have experts and frontline staff working as one. The staff know the process best of all.

10. Where Can We See Real Success With DMAIC?

Does DMAIC really work? Yes. The best example is General Electric (GE). They used dmaic and dmadv are methodologies of in the 90s to fix their factory lines. It saved them billions. It showed on a huge scale that this planned fix gets great results.

This proves that the tools have a real, big effect. On a smaller scale, I saw a hospital use dmaic and dmadv are methodologies of . They cut patient wait times in the emergency room by almost 40%. They did it by checking their process. They used facts to stop bad, pointless steps.

These wins happen every day. They prove that when you use the DMAIC plan well, you can fix tough problems. You can make a real difference.

11. Where Is DMADV Applied?

What about DMADV in the real world? It’s the secret for many good new products. A few years ago, a money tech firm hired me. They needed to design a new phone banking app. Their old one was so bad that a simple dmaic and dmadv are methodologies of fix was useless. They needed a full redesign.

This showed how the tools mean true new ideas. We used dmaic and dmadv are methodologies of . We focused hard on the “Measure” step. We learned what young users wanted: fingerprint sign-in and fast money moves. We designed these in from the start. Their app launch was a big win.

This ready-to-go plan lowers the big risks of any new launch. It makes sure that what you build is what customers want. They will pay for it.

12. Why Is Data Key?

I must say this: Data is everything in Six Sigma. I’ve seen too many projects fail. A team worked on “hunches.” They went by what they felt was true. Data tells the truth. It’s the base of every good choice you make in these projects.

This is why the tools are for a fact-based work style. In a dmaic and dmadv are methodologies of project, the data from the Measure step gives your start line. Your check of that data points you to the true cause. In DMADV, data on customer needs guides every design choice.

You don’t need to be a math genius. But you must respect the data. It helps you see patterns. It finds fixes that you can’t see otherwise. This leads to strong, lasting results.

13. How To Choose the Right Tool?

How do you pick the right plan for your project? I tell my students to ask one simple question: “Am I trying to fix something that exists, or am I making something totally new?” Your answer shows you the right path.

Remember, the tools have different goals. Picking the right one is your first vital step. If your job is fixing an old process with a known flaw, pick DMAIC. Your goal is to make it better.

If your job is to start a brand-new product, or if the process you have is too broken, you must pick DMADV. Your goal is creation. Picking the wrong one is bad. It’s like using a hammer for a job that needs a small tool. You’ll just make a mess.

14. What Are the Long-Term Benefits?

What good results have I seen from firms that truly use this? The benefits are more than just one good project. When you use these plans, you start a culture of constant fixing. Everyone feels they can make things better. That is where a real edge comes from.

Since the tools are Six Sigma methods, they make good money. They cut waste. They boost speed. But the best result I see is the jump in happy customers. When you focus on quality, your customers notice. They stay loyal to you.

In the end, these plans help you build better, stronger businesses. I’ve seen teams and firms change. They make smart choices. They become faster. That’s the real, lasting power of this work.

FAQs

Can dmaic and dmadv be used in all industries?

Yes, dmaic and dmadv are methodologies of Six Sigma that work in many fields like health, tech, and manufacturing to boost quality.

What are the steps in the dmaic and dmadv process?

DMAIC and DMADV are methodologies of Six Sigma. DMAIC has Define, Measure, Analyze, Improve, Control. DMADV has Define, Measure, Analyze, Design, Verify.

Are dmaic and dmadv useful for small businesses too?

DMAIC and DMADV are methodologies of Six Sigma that help small firms fix issues or build better systems to grow and serve customers.